Winter Olympic Village Project

Beijing, China

-

Project Type & Description: Olympic Village, covering the construction, renovation, and commercial operation of the Winter Olympic Village

-

Gross Floor Area: 58,100 m2

-

Total Construction Period: 733 days

-

Main Contractor: China Construction First Group Corporation Limited

-

Project Type & Description: Gsite, BIM+Smart Construction Site

Authentic and Green Olympic Village with BIM 5D

The Beijing Winter Olympic Village Project in 2022 is an industrial benchmark project which won four national awards for Construction engineering in steel Structure, qualified for 2 BIM software copyrights and 2 BIM patents protection.

In addition to that, with the design concept of "Venues Built in the Mountain and Forest, Ecological Winter Olympic Park," this project made significant efforts to maintain the unique historical, cultural, and ecological environmental resources of this village and insisted on minimizing the disturbance to the surrounding mountains and forests. The following details will unveil how this project overcame challenges and endeavors to advance the built environment's sustainable development.

Challenges

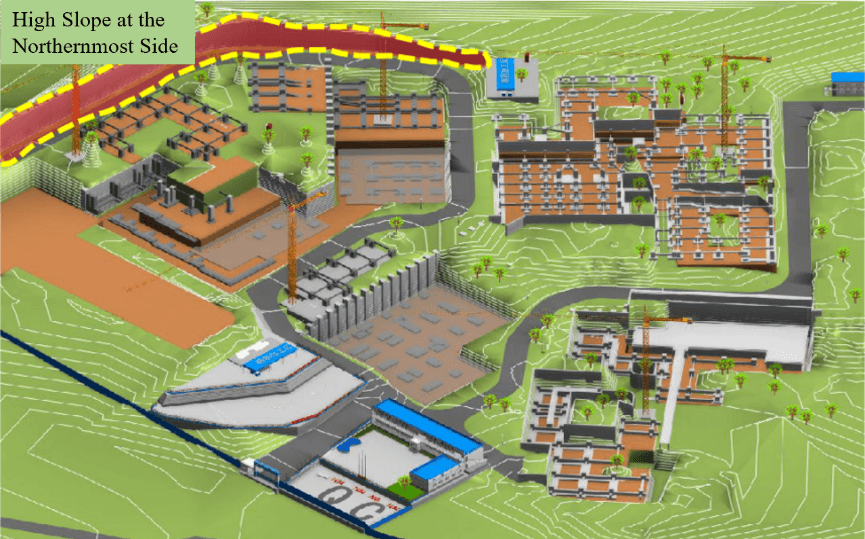

i. High-Altitude Multi-Layer Tableland Topography

This high-altitude mountainous environment has a height difference of 30-42 meters in the east-west and the north-south direction with a small village relic in the middle. Therefore, such topography has to deal with earthwork excavation, site planning, material transportation, and site safety, which requires terrain simulation, and safety monitoring by digital means.

ii. Green Olympics, Ultra-Low Energy Consumption

The project design team adheres to the design concept of the Green Olympics. Thus it is vital to control construction material selection, material processing, and material acceptance conforming to the building standards of ultra-low energy consumption, considering the complex and unique shape of the exterior building envelope and its geographical location.

Implementation

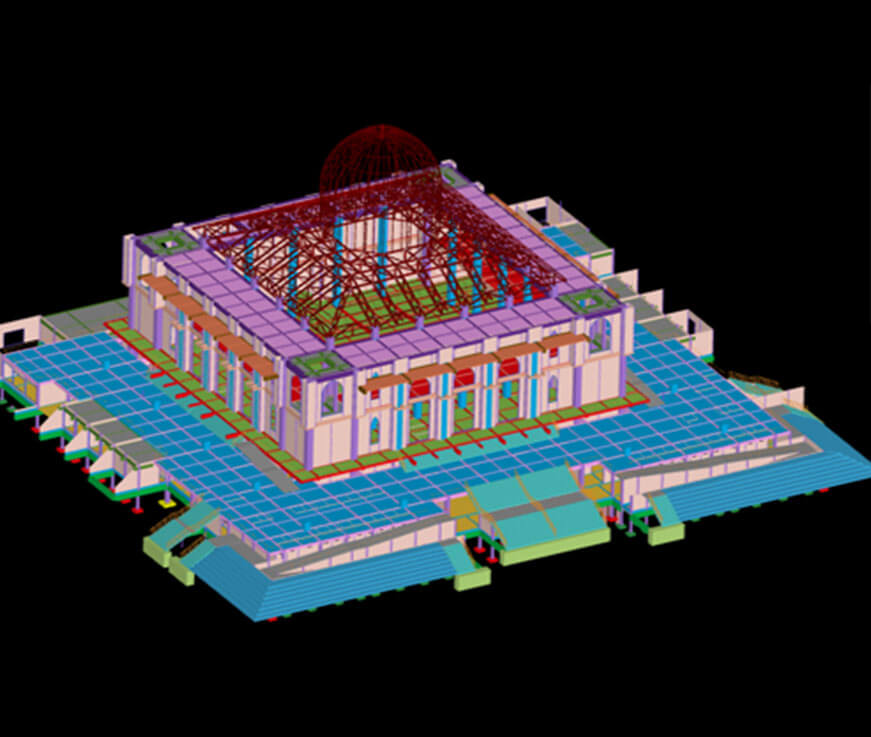

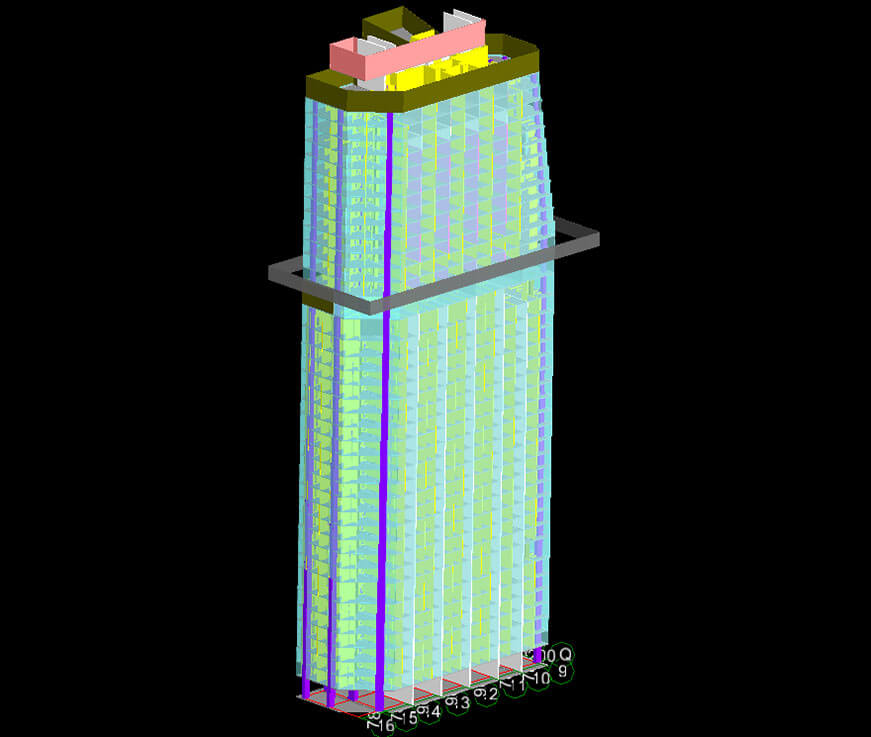

i. BIM Application

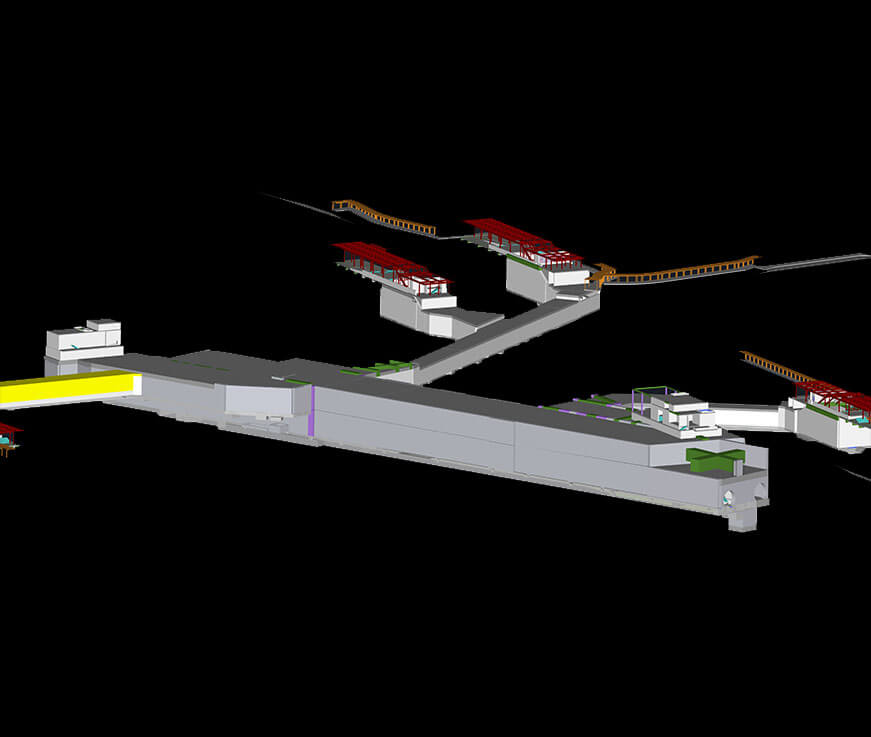

Design Phase: The project team deepened the design of the steel structure and other related specialties, and determine the optimal construction scheme.

Design Phase: The project team deepened the design of the steel structure and other related specialties, and determine the optimal construction scheme.

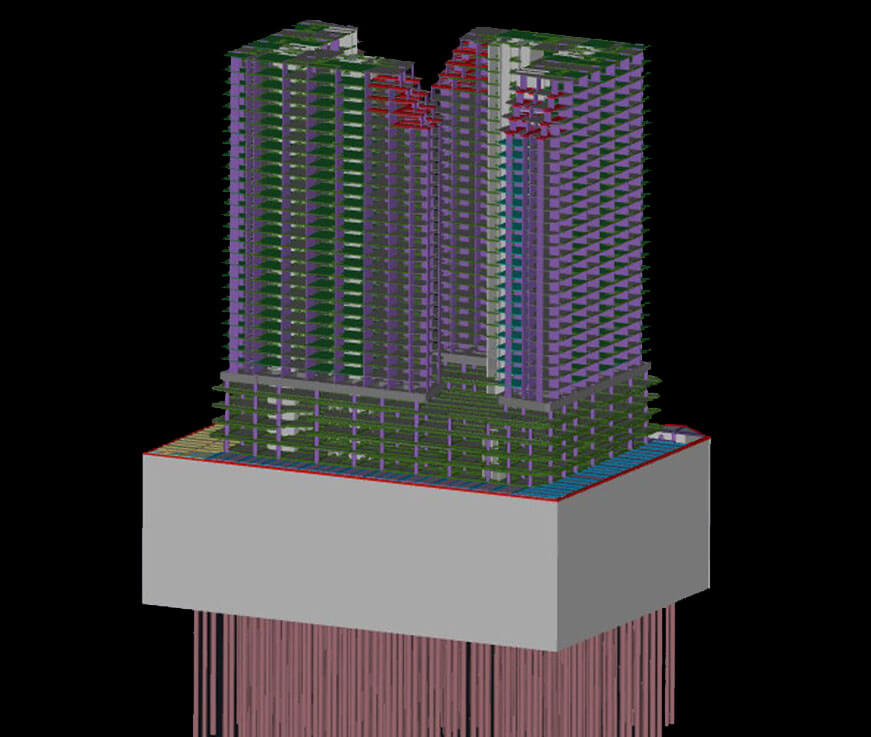

Construction Phase: The team used the Glodon BIM5D to enable the field management, quality, safety, technology, and other departments to collaborate. It also completed the point cloud model of the construction site and check it with the measured data of the earthwork grid and the geological prospecting report. The construction scheme will differ from elevation differences in different construction phases of the alpine site.

ii. Simulation of Temporary Construction Layout of High-Altitude Tableland

The team adopted the 3D scanning technology to collect realistic data of mountains. According to the construction plan, the 3D dynamic & visual planning of the construction site and surrounding living area would be carried out in phases, so as to solve the problem of elevation differences challenges in different construction phases of the alpine site.

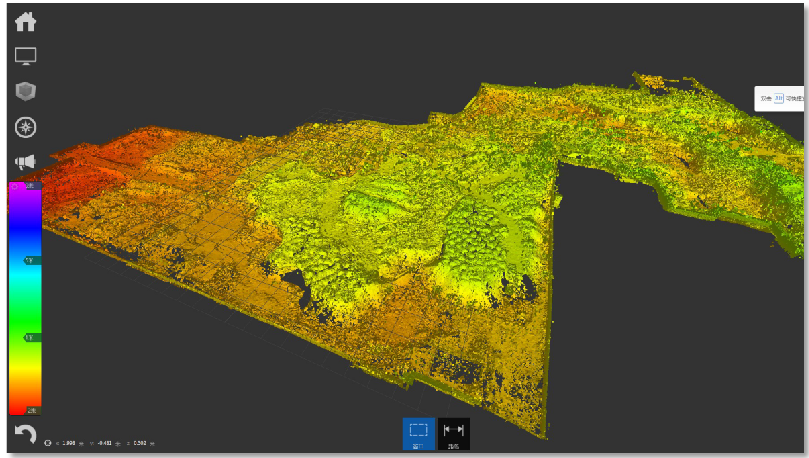

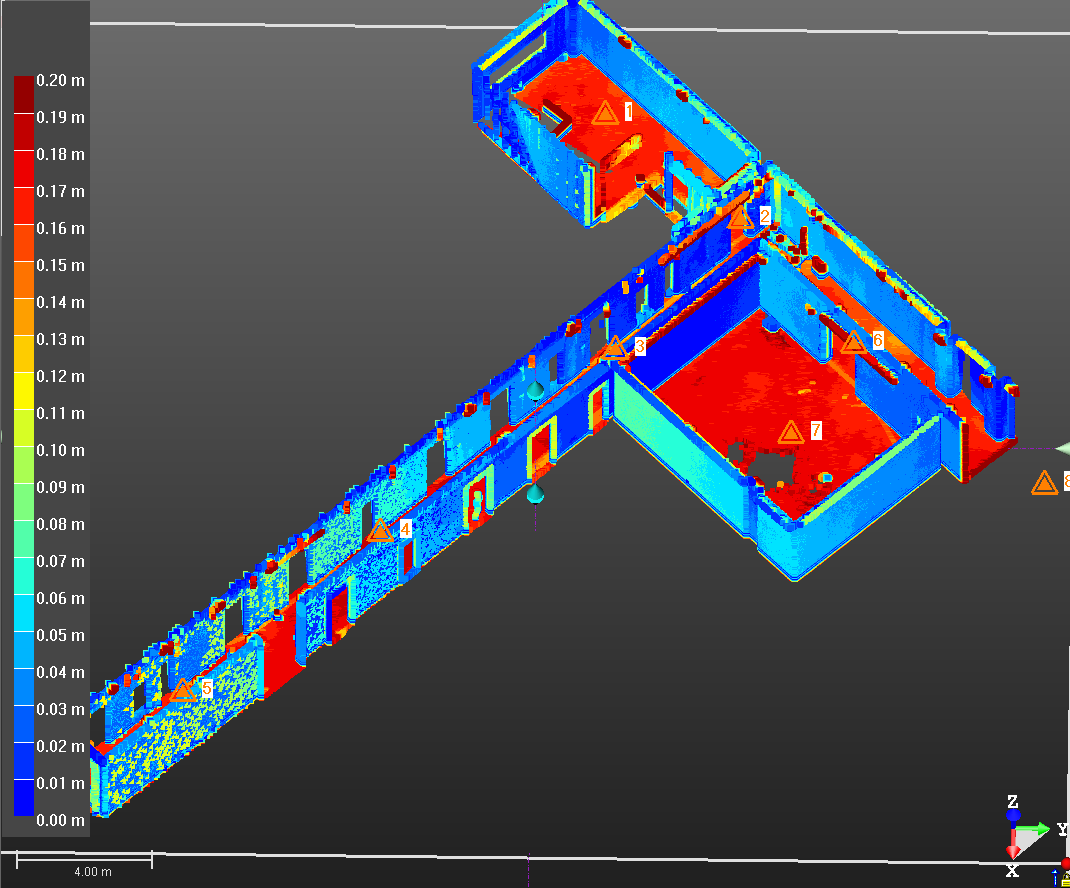

iii. Digital Application of High-Altitude Mountain Topography

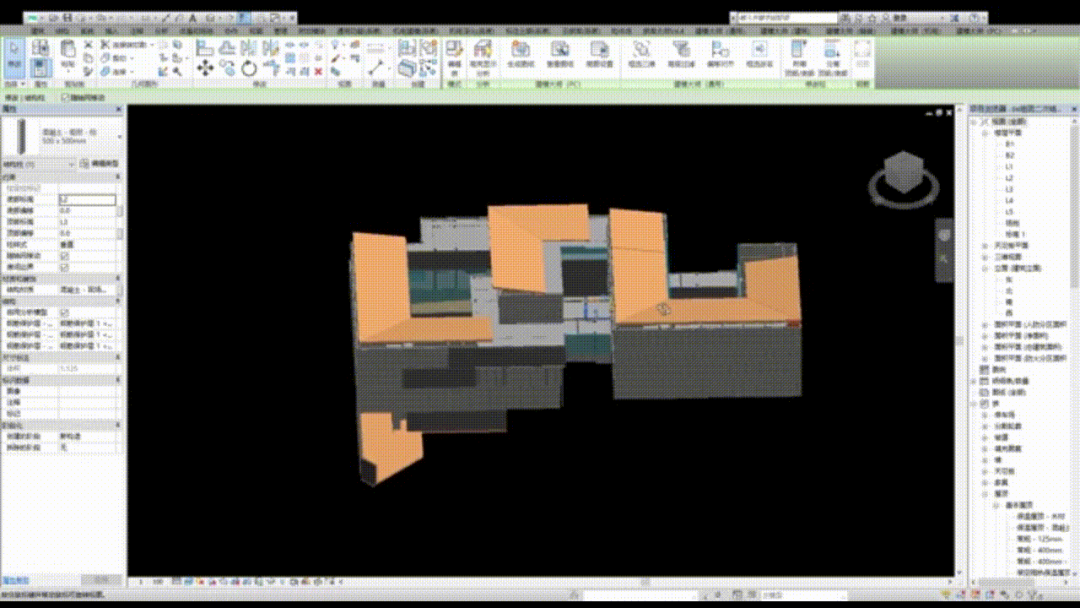

The team utilized digital real-scene capture of mountain topography. By setting up stations at multiple points and scanning the excavated foundation pit earthwork with a 3D scanner, they completed the point cloud model of the construction site with an accuracy of less than 2mm. Moreover, they checked the model with the earthwork grid measured data and generated the geological prospecting report to complete the final digital construction site models.

The team utilized digital real-scene capture of mountain topography. By setting up stations at multiple points and scanning the excavated foundation pit earthwork with a 3D scanner, they completed the point cloud model of the construction site with an accuracy of less than 2mm. Moreover, they checked the model with the earthwork grid measured data and generated the geological prospecting report to complete the final digital construction site models.

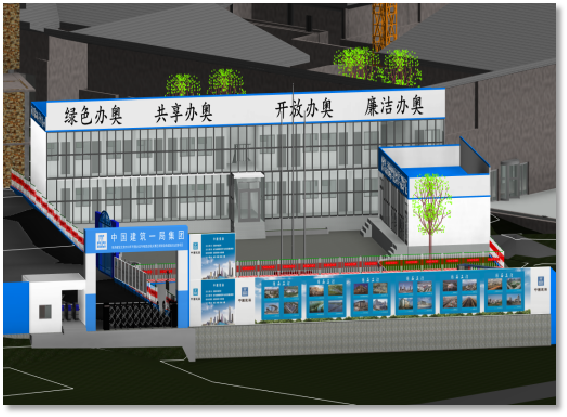

iv. Digital Site Layout Management

According to the standardization manual of enterprise temporary construction in combination with the site construction scheme, the project team carried out CI layout for the mountain office area and construction area of the Winter Olympics Project, so as to meet the requirements of construction safety and cleanliness.

According to the standardization manual of enterprise temporary construction in combination with the site construction scheme, the project team carried out CI layout for the mountain office area and construction area of the Winter Olympics Project, so as to meet the requirements of construction safety and cleanliness.

v. Earthwork Calculation of Mountain Topography

With the data of the 3D scanning point cloud model, the topography model is generated in Revit. When the designed foundation pit model is processed according to the foundation pit and garden elevation of each group, the project team calculated the earthwork balance quantities.

Solution

i. IoT Stress Monitoring System for Permanent High Slope

In the permanent high slope structure with the largest risk factor in the northernmost side of the project, the team installed the IoT stress monitoring sensor, implemented the Building Information Modeling (BIM) in the smart site to monitor the stress changes of the high slope in real-time, and issued stress early warnings in time to ensure the safety of the Winter Olympics.

In the permanent high slope structure with the largest risk factor in the northernmost side of the project, the team installed the IoT stress monitoring sensor, implemented the Building Information Modeling (BIM) in the smart site to monitor the stress changes of the high slope in real-time, and issued stress early warnings in time to ensure the safety of the Winter Olympics.

ii. Formulation of Relevant Standards & Processes for BIM

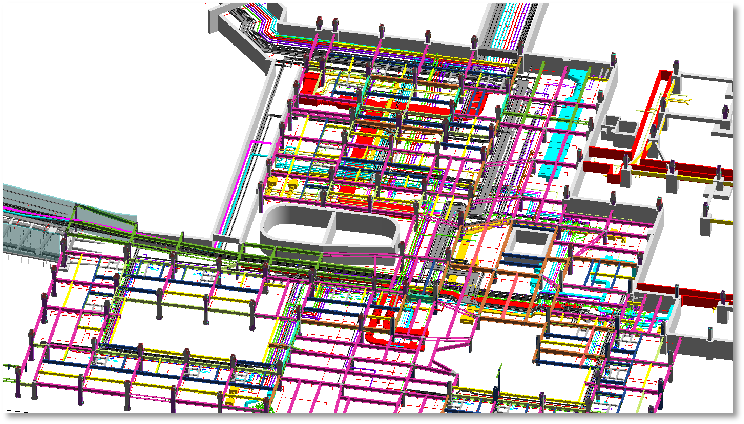

a. Color Standard for Multi-disciplinary Modeling

When Revit integrates with multi-disciplinary models, it is distinguished by color to facilitate drawing communication.

b.Project Template Making

According to the model characteristics of the steel structure discipline provided by the specialized subcontracting of steel structure, the team formulated the project template documents with information such as project reference points, member naming rules, floor axis net, etc. in cooperation with other disciplines.

c. Fineness Standard of Structure and Electromechanical Specialty

The project team specified the specific content of electromechanical modeling fineness, which corresponds to the fineness of steel structures.

d. Solidification of Multi-discipline Model Deepening Process

The team standardized the process from front-end design to general contracting of multi-disciplinary BIM integration, so as to facilitate the work.

iii. Basic application of multiple models based on BIM

a. Structure Discipline

The specialized subcontracting of steel structure shall provide the steel structure discipline model, and cooperate with other disciplines to carry out BIM detailed drawing.

The specialized subcontracting of steel structure shall provide the steel structure discipline model, and cooperate with other disciplines to carry out BIM detailed drawing.

b. Intelligent Electromechanical Modeling of Buildings

On the basis of the structural model, the team carried out a comprehensive arrangement of electromechanical pipelines and the relevant detailed drawings.

On the basis of the structural model, the team carried out a comprehensive arrangement of electromechanical pipelines and the relevant detailed drawings.

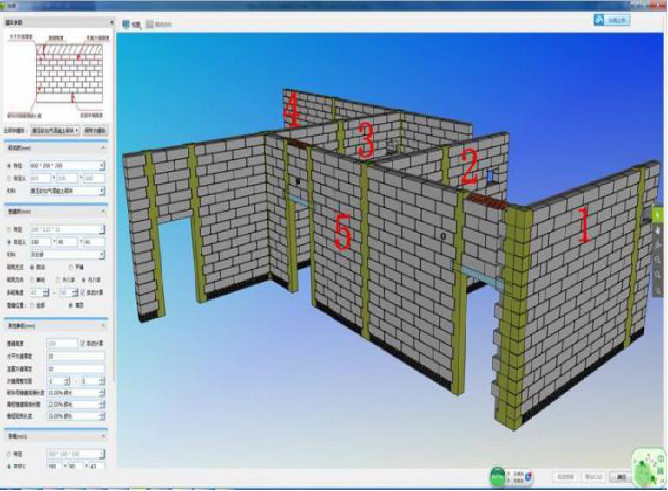

c. Secondary Brick Arrangement

The secondary brick arrangement function of the platform shall be used to deepen the secondary brick arrangement in advance according to the construction plan, and the material list for the arrangement shall be submitted.

The secondary brick arrangement function of the platform shall be used to deepen the secondary brick arrangement in advance according to the construction plan, and the material list for the arrangement shall be submitted.

d. Deepening Ultra-low Energy Consumption Group

The team achieved Building Information Modeling (BIM) for the decoration and design of each group room, completed the detailed design of LOD500, and made drawings for disclosure.

The team achieved Building Information Modeling (BIM) for the decoration and design of each group room, completed the detailed design of LOD500, and made drawings for disclosure.

iv. Collaboration Based on Panoramic Roaming Technology

a. VR Immersive Disclosure

The team used VR equipment to communicate with the technical director of construction subcontracting on key technical nodes such as machine room management, steel structure, secondary structure, decoration, and roof wood tile decoration, etc., and to assess some important processes to improve the disclosure effect.

b.Cloud Collaborative Deepening

The team adopted a cloud-based VR multi-party collaboration function to enable interested parties of the project to work with remote immersive communication technology and reduce communication barriers in the form of model immersion and real human interaction.

The team adopted a cloud-based VR multi-party collaboration function to enable interested parties of the project to work with remote immersive communication technology and reduce communication barriers in the form of model immersion and real human interaction.

v. Secondary Deepening of Electromechanical Installation with Real Scenic Point Cloud

The project team used electronic equipment to implement a 3D scanning for the building space such as the completed corridor and checked the construction deviation by comparing the point cloud model and transmitted BIM in real-time with the tablet computer.

The project team used electronic equipment to implement a 3D scanning for the building space such as the completed corridor and checked the construction deviation by comparing the point cloud model and transmitted BIM in real-time with the tablet computer.

Then, the team imported it into the computer to generate a further electromechanical model superposition with Revit, carried out secondary electromechanical detailed design, and provided relevant drawings and blanking list for disclosure and delivered them to electromechanical subcontracting, so as to improve the feasibility of actual deepening.

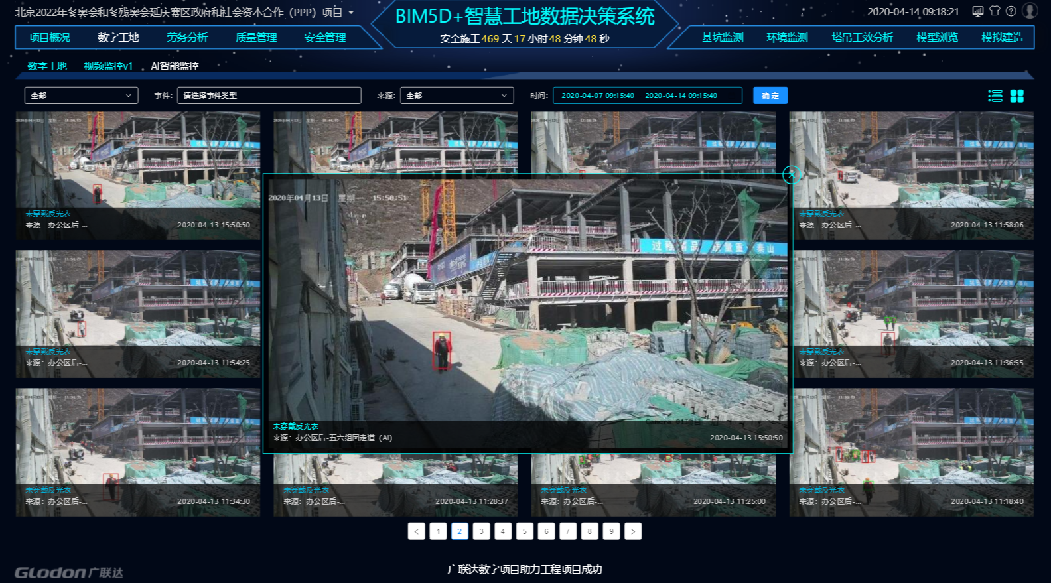

vi. Glodon BIM5D + Smart Site

a. Intelligent Labor Service Management

The site is provided with six regional RF sensors. The workers of the steel structure, municipal and secondary structures of the Project need to wear RF and data storage safety helmets to count the number of construction personnel in each group, record the distribution of patrol labor at night in mountainous areas, and monitor work efficiency.

The site is provided with six regional RF sensors. The workers of the steel structure, municipal and secondary structures of the Project need to wear RF and data storage safety helmets to count the number of construction personnel in each group, record the distribution of patrol labor at night in mountainous areas, and monitor work efficiency.

b. AI Video Image Recognition & Algorithm Monitoring

The image is captured dynamically through the on-site monitoring video, and behaviors such as not wearing a safety helmet, not wearing a reflective vest, not wearing a surgical mask, etc. are dynamically detected to improve on-site safety behavior management.

The image is captured dynamically through the on-site monitoring video, and behaviors such as not wearing a safety helmet, not wearing a reflective vest, not wearing a surgical mask, etc. are dynamically detected to improve on-site safety behavior management.

vii. BIM Facilitating Steel Structure Quality Management

The project team utilized the IoT tracking module of the smart site to correlate the Building Information Modeling (BIM) of important large steel structure components and steel structure corridors with the IoT dynamic QR code, monitored all process data of components from the delivery, transportation, hoisting, and final acceptance stages, and improved the rationality of the steel structure construction plan. ?

Summary of Benefits

i. Economic Benefits

3D scanning + BIM earthwork calculation control saved nearly 60,000 cubic meters of earthwork;

ii. Smart Site Benefits

The IoT smart platform has improved the safety of high slope, reduced workload by 50%, reduced site labor control by 30% of the patrol time, and improved work efficiency by 50% of the video monitoring and AI identification.

iii. Technological Improvement

Through open model and data management throughout the whole process, the workload of data collation is reduced by 40%; with the help of BIM management in the whole process of steel structure, work progress of steel structure tasks is sped up by 30%; work progress of actual survey and measurement is accelerated by 60% with on-site quality inspection of 3D scanning.