Feb 09.2023

A Green, Comfortable and Intelligent R&D Center - Digital Building Benchmark by Glodon

The construction industry is one of the least digitalised sectors in the world and yet responsible for almost 40% of global energy-related carbon emissions. Sustainability factors and digitalisation are now top priorities impacting the future of the built environment. Adopting new digital technologies and solutions throughout the project's lifecycle provides additional opportunities for the new business models and can therefore promote sustainability in the construction industry.

A recent example of how technology promotes sustainability is Glodon’s research and development center in Xi'an, which is officially in service on December 18.

It is the fourth self-owned building built and operated by Glodon that combines and tests Glodon's Digital Building concept with Integrated Project Delivery (IPD), lean construction, digital twins, BIM and other digital technologies.

The exterior of the Glodon (Xi'an) R&D Center

A Green and Comfortable Building That is Energy Self-sufficient

The total construction area of? the building is about 66,000 square meters, with 3 floors underground and 12 floors above the ground. The building has green spaces on the roof and an indoor ecological atrium full of plants. An irrigation system that harvests and utilises rainwater controls humidity and temperature for the plants.

The building achieves energy self-sufficiency with a solar photovoltaic panel system that performs energy generation, noise reduction, and sun shading at the same time. The system can also automatically adjust lighting according to sunlight, which saves energy.

The interior of the Glodon (Xi'an) R&D Center

Inside, the building is equipped with intelligent office equipment to meet the employees' needs for work and leisure. It has an indoor track, fitness zone, and shared relaxing space. In addition, the building is equipped with a healthcare room where people can check their health condition with essential equipment.

The working conditions and environment have been greatly improved. This is not only a microcosm of Glodon's development and growth but also an important step to fulfilling its mission to create a better working and living environment with technology.

An Intelligent Building That Sets Digital Building Benchmark

Glodon is a leading Digital Building Platform Service Provider with products and solutions for the digitalisation of the whole building life cycle. The Glodon (Xi'an) R&D Center is the first self-owned building built with the Digital Building paradigm throughout the entire life cycle and is the best benchmark for Digital Building practice.

Based on BIM, the IPD breaks through silos in the industry and achieves good communication and collaboration among all project stakeholders. The innovative IPD enabled integration to unite the project into one project team, one project plan, one set of business processes, one set of work standards, one set of data, and one platform. It significantly improves project management efficiency and effectively reduces project costs while guaranteeing schedule, quality, and safety.

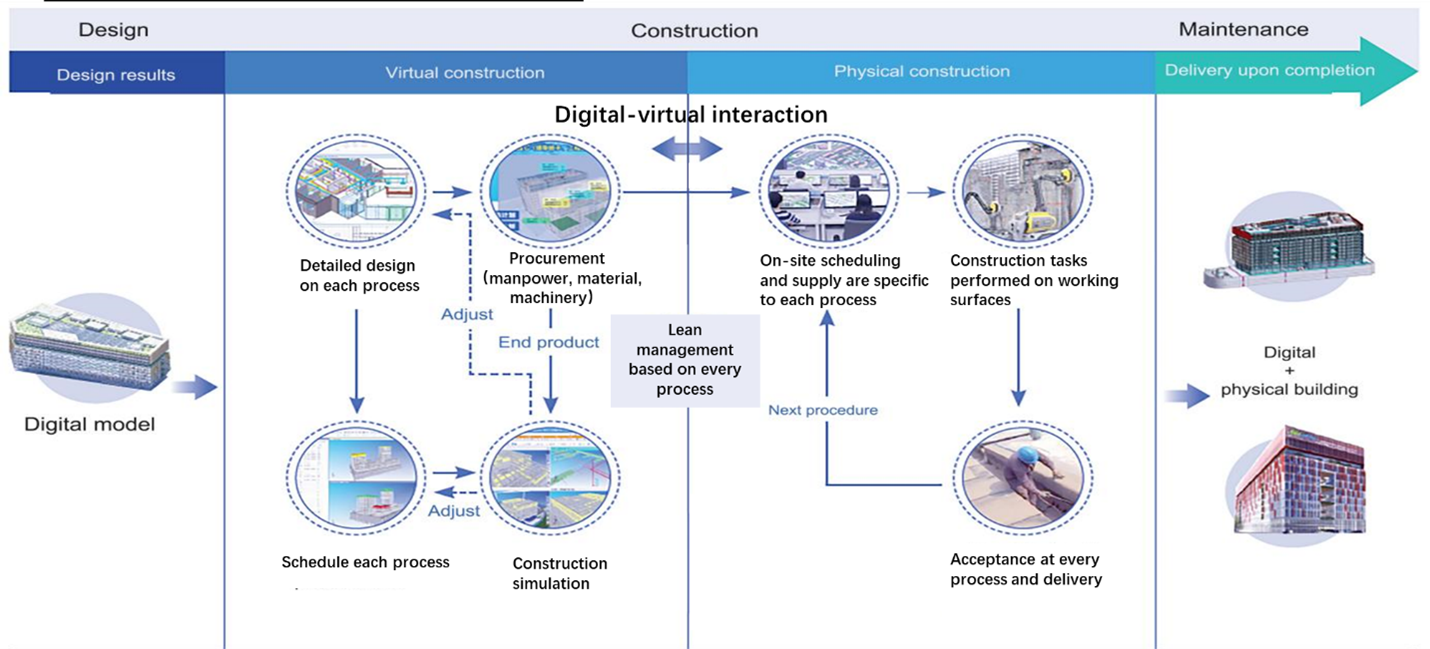

During the construction, the project practised digital lean construction, completed 21,000 project scheduling and delivery processes, and established 680 process standards. The lean construction is also complemented by the digital twin, achieving the integration of virtual and physical construction. In addition, intelligent monitoring of tower cranes, intelligent security helmets, and other software and smart equipment were applied during the process.

Digital Twins Lean Construction

The integration of digital twins and lean construction is the key to the project's success. The digital production line ensured the intelligent scheduling of production, logistics, and construction, while the physical production line enabled perception, analysis, and decision-making on personnel, machinery, and material, and smart construction operations. This maximise value and minimise waste. For example, with the integrated management of rebar, the processing efficiency of stirrups is increased by 4 times, the processing efficiency of hooks is increased by 20 times, the number of rebar processing personnel is reduced by half, and the accuracy of material consumption is improved.

For its successful application of BIM, the project has won several prizes. And the center has also become the digital building software lab of China's National Center of Technology Innovation for Digital Construction.