Apr 25.2022

Understanding Value of Digital Twins in AEC Industry

Digital twins are nothing new, but they have now become a reality and broken into the mainstream thanks to technological advances. The potential applications of digital twins are far-reaching.

Definition of Digital Twins

Definition of it varies, but generally, a digital twin is a virtual representation of real-world entities and processes, synchronised at a specified frequency and fidelity.

Image 1: Future Digital City

Five Levels of Digital Twins

Digital twins can be applied with an increasing level of sophistication or maturity. Some experts see this at five levels:

1.? Descriptive digital twins: for collecting and visualising data.

2.? Informative digital twins: converting data into information for generating insights)

3.? Predictive digital twins: using real-time data to predict a future state.

4.? Comprehensive digital twins: combining levels 1, 2, and 3 to propose interventions for avoiding problems and achieving better outcomes.

5.?Autonomous and connected digital twins: using artificial intelligence (AI) and machine learning (ML) to reduce dependence on human intervention.

Digital?Twin?Life?Cycle?of?Assets

A digital twin can be created at any project or asset life cycle stage. However, the creation of the digital twin, or detailed planning for its creation at an early stage of the life cycle and its use in the pre-project or project stage, is desirable. A clear business case and value proposition must determine when and how a digital twin would be used.

Based on the type of asset and use case, actions needed during the design, construction and handover phase can be as follows. In the case of an existing asset undergoing some type of intervention or a new build, a strong case can be made for creating and using the digital twin in the design stage itself. For a renovation, refurbishment or retrofit project, the proposed design interventions can be added to an as-built model of the existing asset along with the context capture of the environment in which the asset exists. This can be part of the digital twin created during the design stage and used in detailed design, construction and handover. Similarly, the project team can create and use a digital twin from the design stage itself on a new build.

Image 2: Lean Construction of Digital Twin

One comprehensive?example can be a new asset with digital twin provisioning during design and construction and deployed and used for the whole life, including the project stage of the asset. At the design stage, design data and?other digital assets, including a digital replica, are?produced, and the replica is?used for simulation and further what-if analysis. At the construction stage, construction data and?other digital assets are?produced and updated, including an updated digital replica produced along with the physical asset, and used during construction. At?the?handover?stage, digital twin with data, information, and models are?developed and handed over. At?the?operation?stage, the?digital twin is?continually deployed, used, and updated for operation, maintenance, and end-of-life.

Added Value of Digital Twins

The digital twin isn't just a fancy concept, but it's solving significant challenges and is a vital digital transformation element. For the AEC industry, a digital twin is a dynamic, live replica of a built asset or city, which can be utilised throughout the whole life cycle, from design to operation and maintenance.

In particular, whether it is for a completed building, a group of assets, or the process that creates these assets, one of the purposes of a digital twin is to make design, construction, handover and use of these assets more efficient.

The efficiency gains are possible due to the integrated and connected use of data and information. With data and information pertaining to the design, construction and actual performance of the asset, stakeholders gain a better understanding of both the digital and physical versions of the asset.

This allows decision-making to be data-driven, model-centric and collaborative. Digital twins produce real-time data that is actionable, driving insights that can be used to improve strategic, design, operational and maintenance decision-making.

Another key benefit of digital twins is that they dynamically integrate data and information throughout the asset life cycle. This leads to short- and long-term efficiency and productivity gains.?

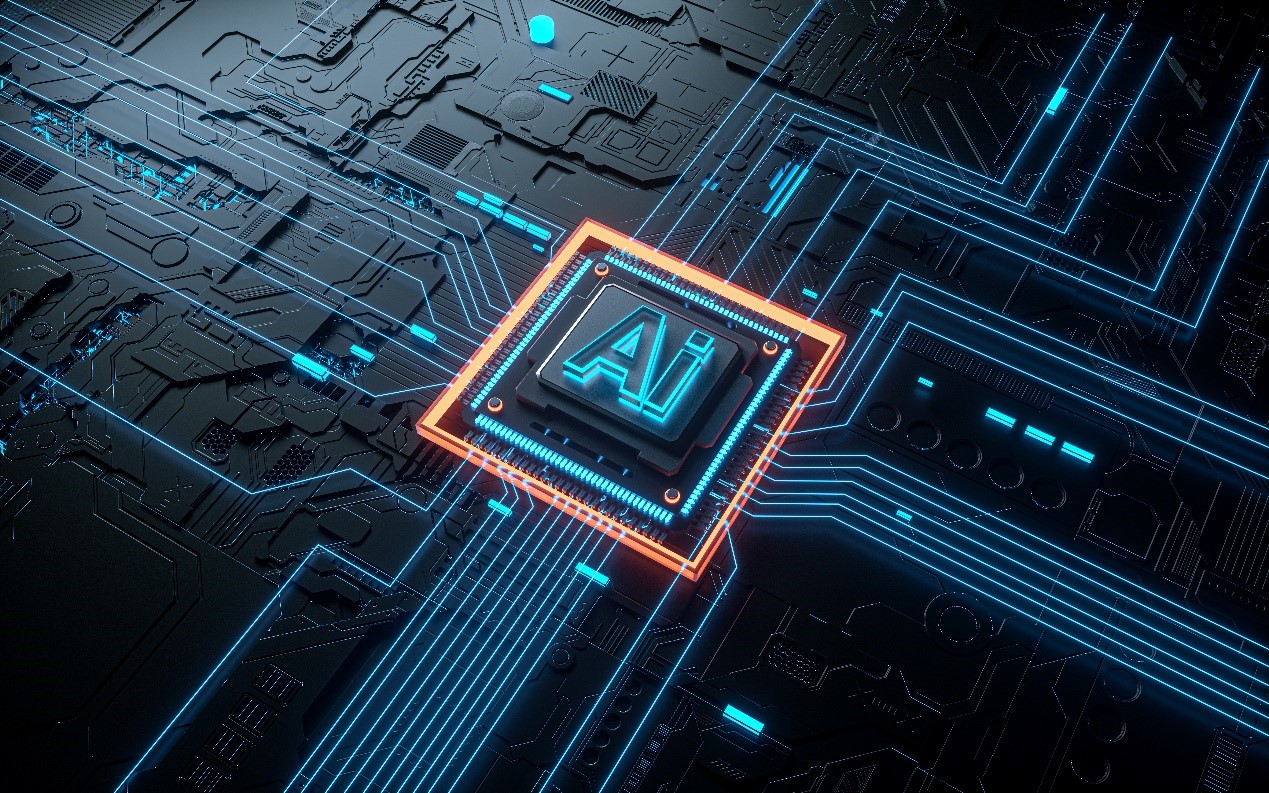

Image 3: A Construction Site

The physical asset cannot be analysed for what-if scenarios; therefore, a synchronised digital version is used instead to remove inefficiencies from the design to improve downstream processes.

Appropriate use of digital twins will add value and provide better outcomes for all stakeholders over the asset's life. Fundamentally, digital twins can help drive better outcomes from the assets, such as improved site safety on a construction project, increased workplace productivity in an office building, or better rider experience on a transit system.

In the context of construction, the core opportunity is to use digital twins to create a tool where construction operations can be viewed as a single system, at different levels of abstraction, and thus managed more thoughtfully at different timescales, organisational levels, and operational scales.

To be accepted, digital twins must create value. The value created must pass the additionality test, they must provide benefits beyond what is possible today with the help of BIM and other currently used model-based and data-driven work practices.

Pilot Project of Digital Twins

Considering sustainability and targets China has, Glodon decided on its latest building investment to meet this target by utilizing the Digital Building Platform. The Xi'an R&D Building ?uses this approach throughout the lifecycle by using an integrated and innovative solution based on the digital twin paradigm.

Image 4: Digital Twin Application in Xi'an R&D Building

Consequently, besides meeting the green (COP26 and Sustainability) targets, the advanced use of digital twin with artificial intelligence over the Digital Building Platform allows the management to understand how to better manage the company's assets. Even during project construction, the real-time digital twin information shows significant results in ensuring achieving goals.